An interview with Ignacio Molina of Padgett Swann Machinery

It is the job of engineers to seek creative solutions to complex problems. These solutions are not always obvious, but the experienced engineer knows that using the highest quality tools makes finding answers much easier. In order to learn what can be accomplished by the correct tools in the right pair of hands, HydroComp interviewed Quality Control Manager Ignacio Molina, of Padgett Swann’s Tampa, Florida USA branch.

Ignacio graduated from university in Cuba in 1994. With a background in mechanical engineering, he began working for Padgett Swann’s marine division (Tampa, FL) in 2005.

Padgett Swann offers a variety of services, such as machining, repair, and manufacture of ship systems. They work with propulsion shafting, propellers, CPP components, heat exchangers, and marine structures. Ignacio started there as a machinist (since there were no engineering positions available at the time) and worked his way up to his current position as Quality Control Manager.

Padgett Swann had been using HydroComp’s PropCad and PropExpert software before Ignacio arrived at the company. Ignacio instantly recognized the software’s potential. “I found PropExpert was a very useful tool for what we do,” Ignacio explains. He tells us how he uses the software to calculate the relationship between propellers and engines: obtaining the RPM-horsepower curve. PropCad was very helpful geometric design, as well as reverse engineering for inspection.

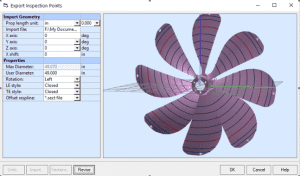

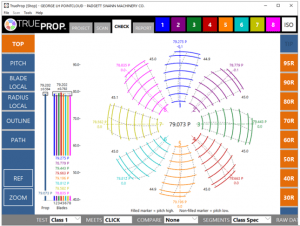

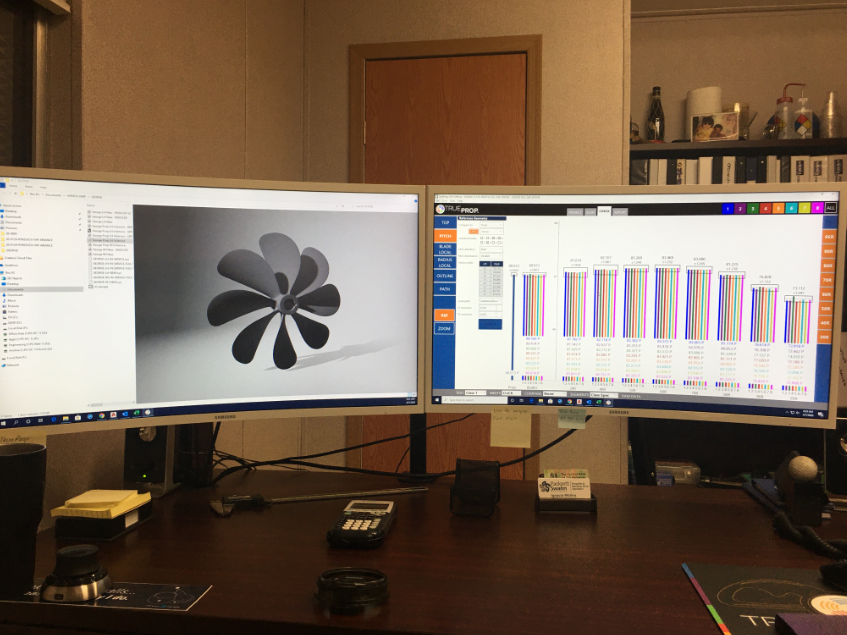

Recently, Ignacio has become more involved with HydroComp’s new sister company, TrueProp Software LLC. TrueProp is software for propeller inspection and repair. Now Ignacio incorporates both TrueProp and HydroComp’s PropCad CAD software, along with their digital pitchometer, to inspect propellers and generate reports.

Recently, Ignacio has become more involved with HydroComp’s new sister company, TrueProp Software LLC. TrueProp is software for propeller inspection and repair. Now Ignacio incorporates both TrueProp and HydroComp’s PropCad CAD software, along with their digital pitchometer, to inspect propellers and generate reports.

“TrueProp is efficient, effective and accurate. It captures everything we need, everything we are looking for. Combined with our other technology, it generates reports very quickly as well.”

This is important for Ignacio, since Padgett Swann works with a large variety of propellers, some so big that during inspection they require the machinery to be realigned several times. “No matter how careful you are, you always lose accuracy when you have to realign. There’s no preventing it.”

Though TrueProp is developed marine propellers, Ignacio has found it useful in other circumstances. He has also been applying TrueProp to inspect and reverse engineer water pump impellers. The software has allowed him to inspect the pitch and other geometry of this different kind of system.

Padgett Swann and TrueProp have also been developing new inspection integrations, using general purpose laser scanning technology to perform a non-contact inspection of the propeller. This technology is a unique to TrueProp – allowing our users to inspect propellers without ever removing them from the vessel. Several of our TrueProp customers are using this technology to scan large propellers.

Over the years, Ignacio has developed a very close relationship with HydroComp staff. He’s been to training classes and frequently benefits from HydroComp’s customer support. He speaks about the staff with great familiarity: “Any time I call it is like talking to a good friend. The staff knows about all sorts of little things that we use here all the time. All of my questions are answered, and I am always given the help I need.”

HydroComp’s Adam Kaplan comments on his close professional relationship with Ignacio: “Working with Ignacio and the team at Padgett Swan is a pleasure. We have been supporting them for many years with their use of PropCad and PropExpert. Ignacio and I work together regularly through phone, email and screen-sharing sessions. Ignacio uses almost every feature in PropCad and TrueProp – it has been a very beneficial partnership that has led to new capabilities for their company and robust software improvements for HydroComp and TrueProp

HydroComp’s Adam Kaplan comments on his close professional relationship with Ignacio: “Working with Ignacio and the team at Padgett Swan is a pleasure. We have been supporting them for many years with their use of PropCad and PropExpert. Ignacio and I work together regularly through phone, email and screen-sharing sessions. Ignacio uses almost every feature in PropCad and TrueProp – it has been a very beneficial partnership that has led to new capabilities for their company and robust software improvements for HydroComp and TrueProp

Ignancio’s relationship with HydroComp has been a recipe of keen minds, superior tools, and the desire to continually improve and educate. When someone like Ignacio is offered continued opportunities to advance their craft, they don’t waste time. By coupling this energy with cutting edge advanced propeller tools, there are no limits to what can be accomplished.

Download the full interview here: PadgettSwannInterview.pdf

For more information, please contact:

|

HydroComp, Inc. Tel +1.603.868.3344 Jill.aaron@hydrocompinc.com www.hydrocompinc.com |

Padgett Swann

Tel +1.813.247.3478 imolina@padgettswann.com www.padgettswann.com |