Efficient design-stage investigation of EEXI compliance

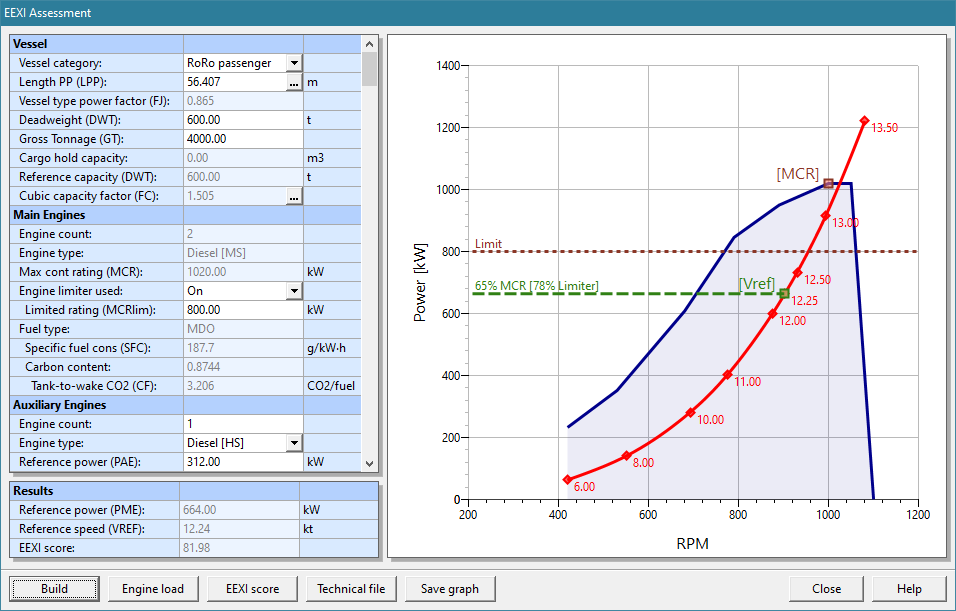

Suitable for virtually all ships under EEXI restriction, the EEXI Assessment utility in NavCad Premium provides quick and resource-friendly design guidance when the need comes to investigate where a ship stands regarding EEXI compliance. At the conclusion of the evaluation, the generated report can be used as reference documentation for quality assurance and benchmarking of future EEXI compliance calculations.

EEXI Requirements Affect Ships as Small as 400 Gross Tons

Most discussion about EEXI relates to large ocean-going ships, run by large companies with substantial resources. However, the EEXI requirements affect ships as small as 400 Gross Tons, and the process to obtain compliance certification can be intimidating and costly for companies running these vessels. This is particularly true during design-stage assessment of EEXI compliance, where the objective is not to prepare the “Technical File” for submittal but to investigate the current EEXI compliance status of a ship. This business planning stage can require multiple computations to evaluate the various options necessary to achieve compliance.

Compliance simply compares an EEXI “score” to a ship-type criteria, so why are EEXI compliance calculations so difficult and costly? The reason is principally to ensure appropriate commonality for each submittal, so that no one can “game” the calculation of the score. This requires the prediction of an approved speed-power curve from which is extracted a reference speed, power, and fuel rate. This has led to a set of requirements that are intricate, require a narrow definition of acceptable methodology, and can only be accepted from approved and verified providers (such as Classification Societies).

Numerical Computations

These are narrowly prescribed as CFD calculations that implement “Reynolds-Averaged Navier-Stokes equations”. To utilize CFD, however, practitioners are required to demonstrate qualification in CFD computations and to conduct calibration/validation studies as part of the calculation of the reference speed-power curve.

Model Tests

Tank tests of resistance, self-propulsion, and/or propeller open-water performance following ITTC-1978 guidelines can be utilized in the calculations. This includes tests for ship load conditions that are different from the prescribed EEXI draft condition.

Sea Trials

Trials conducted for normal business and operational planning are typically insufficient for use in the prescribed EEXI methodology. Approved trials must be conducted according to ISO or ITTC recommendations.

While the intent of these prescribed computational methods is laudable from the regulatory perspective, there needs to be a distinction made between what is needed for the strict requirements of compliance and what is useful and appropriate for design investigations. In fact, reliable – and technically valid – alternative methodologies are available.

Effective resource-friendly evaluation of the EEXI score for design investigation is available with the EEXI Assessment utility in NavCad Premium Edition.

EEXI Assessment in NavCad Premium

NavCad®

Once the system simulation model is in place and the equilibrium calculation of the speed-power curve complete, it is a simple matter to run the EEXI assessment. Consider and evaluate various mitigation options with NavCad, including engine limiters, different fuel types, propeller modifications, even hull cleaning.

Hydrodynamic and Propulsion System Design Tools

NavCad®

The flagship framework for entire resistance, propulsion, mission profile, and optimized performance design tasks

PropElements®

HydroComp’s “design for performance” propeller tool to customize and optimize a propeller for a specific ship or vessel type